TECHNICAL INFORMATION

Plastic Molding Technology

We meet customer needs with flexible ideas and the veteran skills to achieve your vision.

Let’s take a look at some of the injection molding technologies we have to offer at Daimei.

More beautiful

Thanks to over 50 years of manufacturing plastic exterior components at Daimei, we can showcase some of the knowledge we have cultivated in dedication to shapes, along with more beautiful, higher quality finishes.

Mastering the beauty of plastic

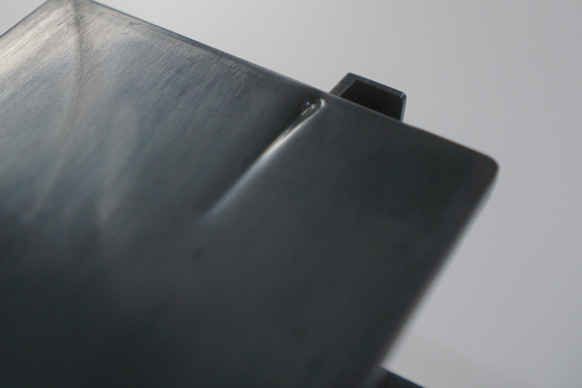

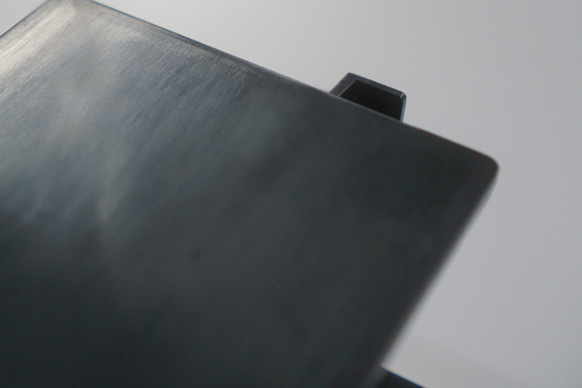

Weldless molding (Heat&Cool molding)

In formation of plastics, weld lines*1 and sink marks*2 are synonymous with exterior defects.

Filling a mold heated to a high temperature of 100℃ with plastic vastly improves its fluidity, making weld lines and sink marks less noticeable.

Also, because we can neatly transfer the patterns of the mold, the exterior properties are improved, resulting in a high-gloss, mirror-like surface finish.

This process is used for household appliances and automotive components to make the exterior look better.

*1Weld lines: A striped mark occurring where two pieces of plastic are joined

*2 Hiccups: A dent due to differential shrinkage caused by uneven cooling

Designing the best mold

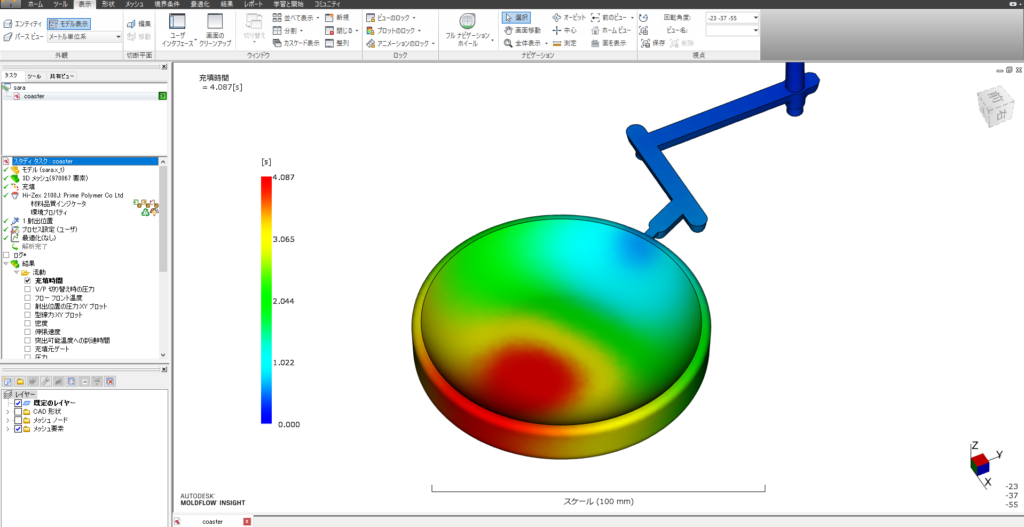

CAE flow analysis (Moldflow)

Changing the design after making the CAE flow analysis mold entails significant modification costs, and can result in remaking the mold in the worst case scenario.

We use CAE flow analytics simulations to create the exact shapes our customers want while keeping mold production costs low.

By considering product issues in advance, we can prototype and mass produce products of higher quality while keeping costs down.

More functional

Let’s take a look at some of the techniques we use in order to maximize the functionality of plastic and bring out performance that goes beyond plastic performance, making products more user friendly.

Development of material tie-ups and establishment of molding methods

Metal alternative plastics

Metals, such as magnesium, have conventionally been used for household appliance housings due to their strength and fire-resistant properties, however, working with another manufacturer, we have jointly developed a material and established a formation method that delivers the same strength and rigidity using plastic. This has resulted in a material that is lighter and much cheaper to manufacture than metals.

Carbon fiber reinforced plastic

Adoption example: Digital 4K Camera housing

Lighter and easier to use

Gas Assisted Injection (AGI)

Plastic is now being used as an alternative to metals and wood in order to keep product weight down. To make plastic even more lightweight at Daimei, after injection into the mold, it is filled with gas like a balloon, succeeding in creating cavities inside the product.

Finishing straight without warping

Gas Press Injection (GPI)

We use molding technology to deal with the difficulties of plate-shaped products warping and not fitting into other products due to unstable dimensions.

JP

JP EN

EN